When I began working on my cider-tasting notebook, 33 Mugs of Cider, I drank a lot of craft cider. I fell in love with the liquid I was sampling, but I quickly realized that cider lacks an important element of drinking culture – a vessel with which to appreciate it.

After all, wine has the goblet. Brandy, the snifter. Beer has the stein, and the pint glass, and the ... you get the idea. I tried sampling cider using my not-small collection of beer and wine glasses, but nothing seemed quite right.

So I set out to create something purpose-built to enhance the experience of drinking craft cider. This is what I came up with. I hope you enjoy it.

interiorCOLOR & CLARITY

When you examine cider in a clear glass, you’re seeing the color of objects around the cider, not just the cider. With the Cider Tasting Mug, the opaque white walls of the interior allow you to see the cider’s true color and clarity.

EXTERIORPURPOSE-BUILT TO

ENHANCE HARD CIDER

- TAPERED NECK

Aromas gather in the tapered neck, concentrating them right where your nose will meet them.

- IT’S CERAMIC

Glass is great, but ceramic is better, at least when it comes to insulating properties. Cider stays cooler longer in ceramic.

- WIDE MOUTH

Go ahead, don’t be shy. Put your nose near the cider where its aromas are most powerful.

- HANG STRAP

The Nevada-shaped pierced tab provides a nice spot to rest Web Space No. 1 (the not-very-creative medical term for the webbing between your thumb and index finger).

- UNGLAZED

While the interior and lip of the mug are coated with a smooth, bright white glaze, the rest of the interior is left raw, providing a firm grip, even when wet.

DESIGN EVOLUTION

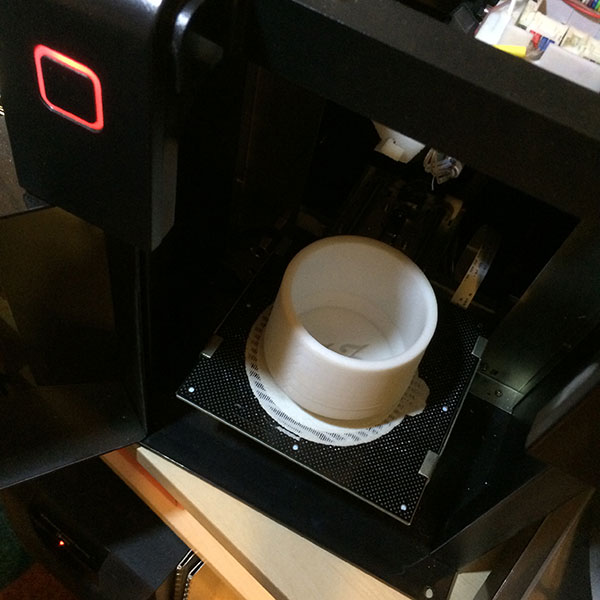

It started as a sketch, made its way to a 3D printer, was refined on a potter’s wheel, field-tested by some of America’s leading cidermakers, and finally, poured and glazed by hand for you in Portland, Oregon.

- TOO TALL, TOO MANY HANDLES3D PRINT

- STILL TOO TALL3D PRINT

- TOO THICK3D PRINT

- TOO SPATTERED,

NOT ENOUGH HANDLESWHEEL-THROWN BY SAM KASHUK - JUST RIGHT.

ON TO CASTING!WHEEL-THROWN BY SAM KASHUK

HOW IT’S MADE

I wanted something that — like cider — felt unpretentious, organic, sturdy … and local. Something that leveraged cider’s long history as agricultural produce, but which felt at home on the modern table. I found a great local partner in Mudshark Studios, who cast and finish each mug by hand here in Portland, Oregon. Like snowflakes or apples, no two are alike.

After gluing the two halves together, I painted and carefully polished the surface in advance of mold-making.

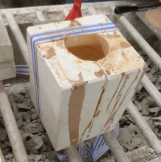

A mold is made from two pieces of interlocking plaster. Here, clay has been formed around half the proto. Plaster is ready to be poured into the wood mold, forming the first half.

Plaster is now poured into half the mold. The plaster is in a liquid state but will dry within a few days, at which point the clay can be removed and the other half poured in plaster.

The completed plaster mold. Liquid clay (aka “slip”) is poured through the hole in the top of the mold. After 5-10 minutes, the slip is poured out, leaving a thin veneer of clay inside.

The “33” logo is embossed in the bottom of the still-soft mug. After this step, the mug is trimmed and smoothed before an initial kiln firing.

The first firing produces a whitish state called “bisque.” Mmm, bisque. At this point the mug is hard, but still needs white glaze added. The interior glaze is poured with a pitcher.

With careful masking, the lip of the mug is dipped into a bath of white glaze, producing a crisp line of white glaze.

After firing, the final step is hand-tying a length of USA-made leather to each mug before packaging.

BUY NOW

BUY NOW